At Agentdraw, we understand the critical importance of thorough testing and validation in the development of your products. Whether verifying that a product meets specific requirements or ensuring compliance with industry standards and regulations, our experienced product development team manages the entire testing process. We ensure that you are fully informed at every step, providing peace of mind that your products will perform as expected in the marketplace.

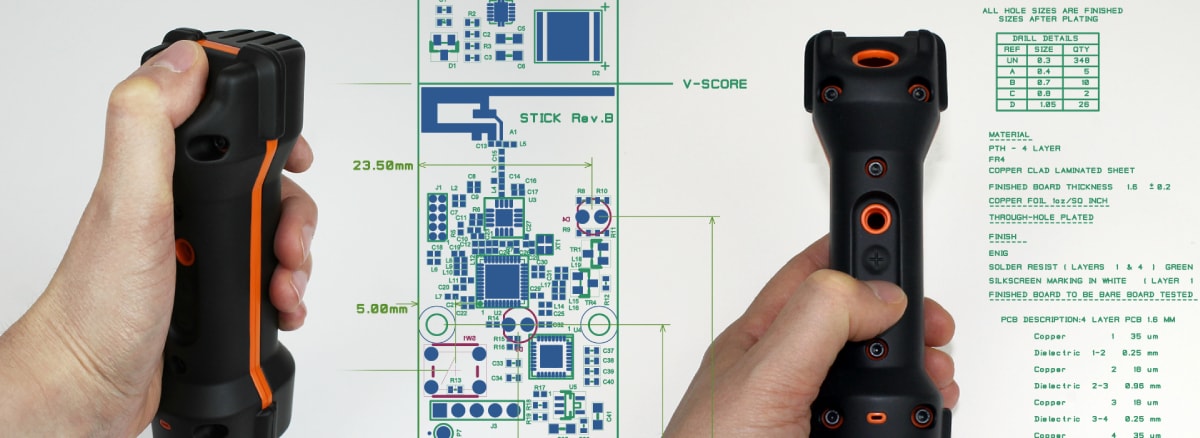

The level of testing required can vary significantly from one product to another. We often employ advanced prototypes to conduct comprehensive physical testing and evaluation. This critical phase helps validate not only the design but also the material choices, ensuring that every component functions perfectly under real-world conditions.

For products that must adhere to strict regulatory standards, Agentdraw collaborates closely with accredited external test houses. This partnership ensures that all solutions not only meet your specifications but also achieve the necessary certifications, approvals, and markings. Our proactive approach streamlines the compliance process, making it smoother and more efficient.

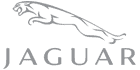

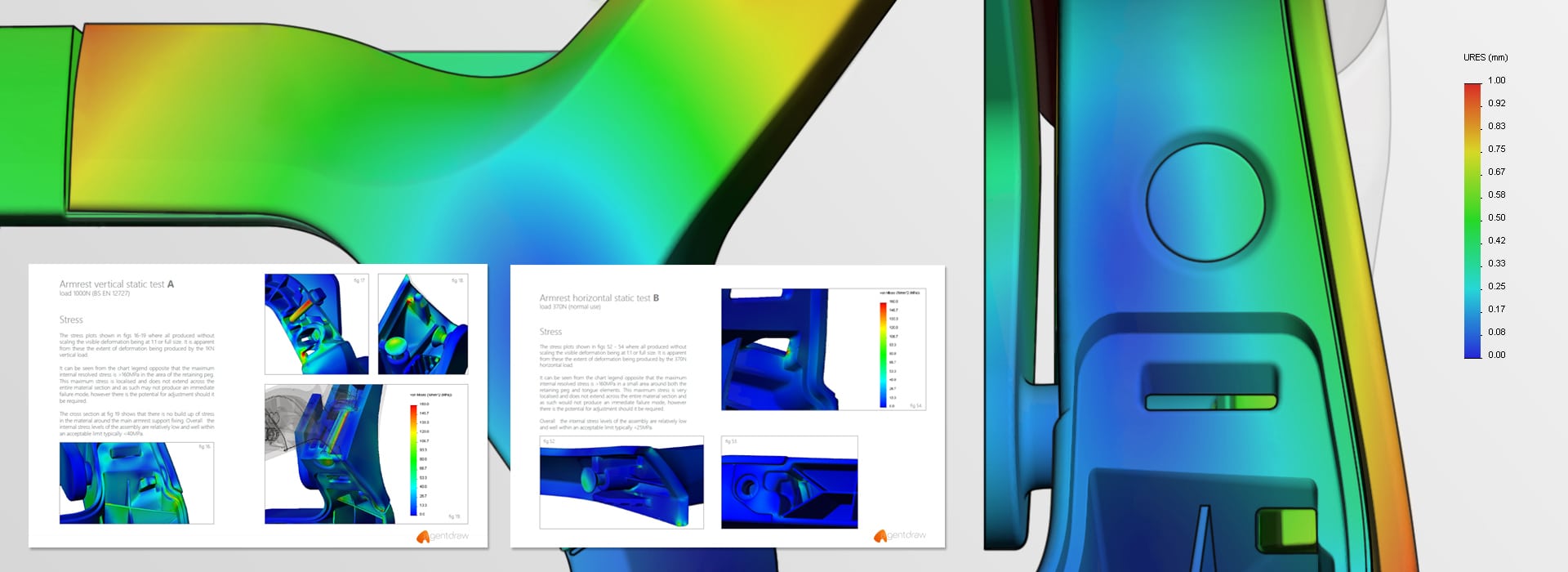

In addition to physical tests, we also offer virtual testing capabilities, including Finite Element Analysis (FEA). This sophisticated digital process allows us to simulate and analyze the performance of parts and assemblies in a controlled virtual environment. FEA provides essential insights into the durability and structural integrity of components, predicting how they will behave under various stress conditions and environments before they are physically manufactured.

Ready to ensure your product’s performance and compliance with the highest industry standards? Contact Agentdraw today to learn more about our comprehensive testing and validation services.